Recently, the third National Communication Conference on Intelligent Manufacturing Innovation Achievements in the Automotive Industry was held in Qingdao. At the meeting, Guangzhou Risong Hokuto Automotive Equipment Co., Ltd., a subsidiary of Risong Technology, won the title of "High Quality Supplier of Intelligent Manufacturing System Solutions for China's Automotive Industry" in 2022.

This meeting brought together leaders and academician experts from relevant national and local departments, leaders, experts, professors from scientific research institutes and universities, as well as relevant management and technical personnel from numerous automobile manufacturing enterprises and automobile supplier service providers across the country. It was sponsored by the China Equipment Management Association and co sponsored by FAW Jiefang Qingdao Automobile Co., Ltd.

Previously, Risong Hokuto was awarded the title of "Excellent Supplier for User Satisfaction in the Automotive Industry" in the 2020 evaluation and recommendation activity for excellent suppliers for user satisfaction in the automotive industry conducted by the Automotive Intelligent Manufacturing Technology Center of the China Equipment Management Association.

The recognition of this honor again is not only the recognition of the value created by the Ruisong project case, but also the recognition of the company's innovative technology research and development strength, and also the recognition of Risong's service ability and level.

Risong's "turn key" project delivery "peace of mind and satisfaction"

Risong has participated in the entire process from project initiation to project completion, and worked with customers to jointly design. It not only brings operational control technology application experience to customers, but also relies on thousands of engineering project experiences to provide customers with process applications in project related fields. In many non-standard cases, it finds common ground, and then reversely applies it to projects to achieve efficient development and ensure customer production quality.

The core of Risong's "turnkey" project is to solve the technical application problems of combining operation and control technology with equipment technology, tailor it to the actual needs of customers, shorten the project development cycle, improve the production and manufacturing quality of customers, reduce costs, and provide customers with an integrated system project that can maintain and worry-free completion of production tasks. What is delivered to customers is a sense of peace of mind and satisfaction.

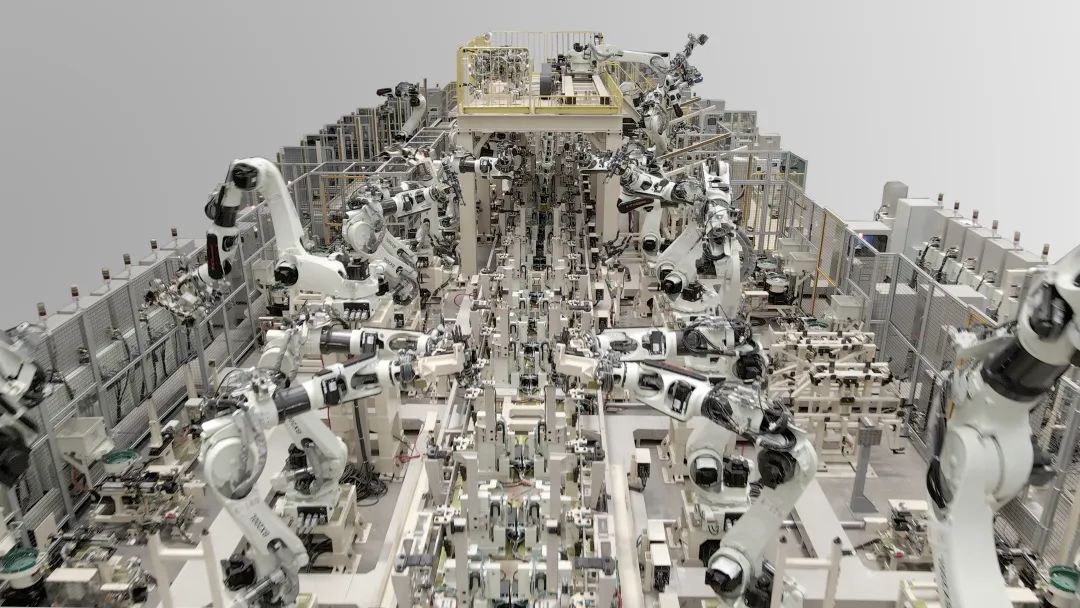

A typical case of intelligent manufacturing for automobiles: intelligent door cover assembly and adjustment line

The car body in white door cover assembly line is the most difficult production line in the automotive field in terms of automation. Risong Technology has launched the first fully automated, intelligent and flexible car door cover production line in China and has taken the lead in achieving mass production. The intelligent assembly and adjustment line for the door cover achieves fully intelligent assembly of four doors, two covers, bumpers, and interior bolts, achieving the expected goal of "saving people and reducing costs.". At the same time, it realizes random mixed production of 8 models, and the entire line reaches 54 seconds to complete the intelligent assembly of one car, four doors, and two covers! The comprehensive adoption of high-tech automation solutions - "intelligent visual guidance technology", "intelligent tightening technology", and "intelligent quality control technology" - has achieved a number of core technologies that are leading in China and internationally advanced, making it a model line case for intelligent manufacturing in the industry.

Intelligent manufacturing and assembly line for four doors and two covers of automobiles

This production line utilizes advanced digital virtual debugging offline simulation technology, virtual visualization and assembly, and offline program verification and improvement to reduce planning and design errors, effectively reducing on-site debugging time and risks. Using machine vision technology to achieve efficient machine intelligence, using laser measurement technology to measure the gap surface difference between the door and the vehicle body after matching, and automatically adjust and optimize it. The quality control system can track the assembly quality of each vehicle body at any time, monitor the information of each production cycle, and form a complete closed-loop system from fully automatic production to quality monitoring and feedback on the production line.

The largest manufacturer of automotive intelligent equipment technology research and development

Risong is one of the earliest companies in China to provide intelligent solutions for automotive equipment, and is also the largest automotive intelligent equipment technology research and development manufacturer in China. It provides overall turnkey engineering services for automotive manufacturing, including preliminary process plan analysis, overall line planning, design, manufacturing, debugging, and installation. Long-term service to well-known automotive industry enterprises such as GAC Group, Chang'an Group, Toyota, Honda, Mitsubishi, Mazda, GAC Passenger Cars, Geely Automobile, GAC Aian, BYD, Xiaopeng Automobile, Hechuang Automobile, Zero Running Automobile, Light Orange Age, etc.

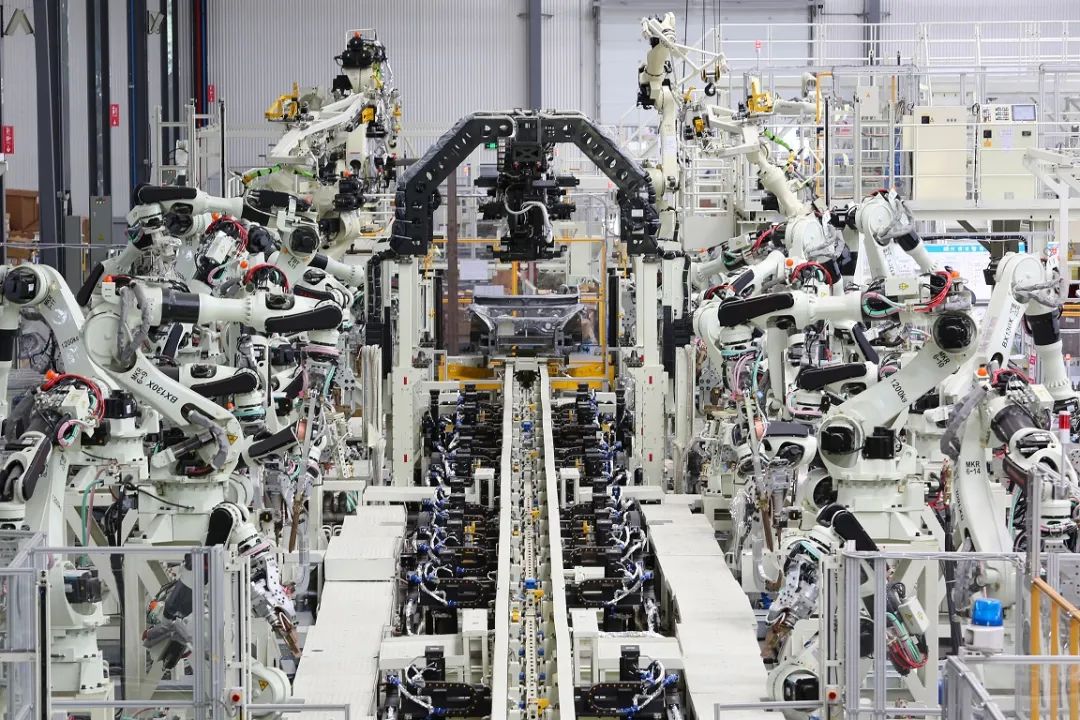

Flexible Intelligent Assembly Production Line for Automobile Manufacturing

Flexible intelligent welding production line for steel aluminum body of new energy vehicles

Risong is the core supplier of Toyota's first overseas factory on the latest TNGA platform, and has helped GAC Toyota become one of Toyota's global model factories; For the first time, GAC MOTOR, an independent brand, has realized unmanned production of its entire production line, achieving or even surpassing world-class production line efficiency and intelligent flexibility; Providing technical support for the production of independent brand GAC new energy vehicles using aluminum body and lightweight design for the first time, successfully breaking the technical blockade imposed by international giants in this field; The four door and two cover assembly line provided for Mazda Automobile is the first flexible intelligent door assembly and adjustment line independently developed and first mass produced in China, and is an internationally advanced model case.

Based on the technical foundation of Beidou in Japan for nearly 50 years, Ruisong has accumulated a large number of innovative technological achievements and mature project experience in the field of automotive intelligent manufacturing, with comprehensive capabilities ranging from process planning, overall line layout, style formulation, 3D design, 3D dynamic simulation, drawing design, and off-line program output.

In the future, Ruisong will continue to provide higher quality and more innovative overall technical solutions for the automotive equipment industry, striving to become a leading enterprise in the field of intelligent manufacturing in the automotive industry.