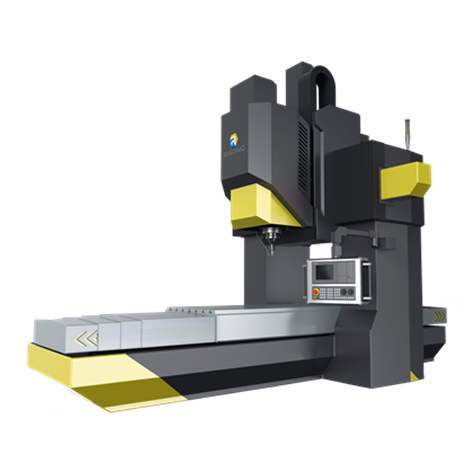

The gantry friction stir welding equipment is a piece of high-end welding equipment developed based on the concept of a high-end CNC machine tool. At the beginning of the design, the overall structure, after full optimization of its finite element mechanical structure and matching in kinematics/dynamics, is able to ensure the rigidity and motion stability of the machine tool body. The main body of the equipment is made of high-quality castings treated by double tempering, rendering the equipment excellent in accuracy retention; the constant overhanging head is designed to keep the friction stir welding head's accuracy consistent in the Z-direction space; the equipment is manufactured according to the machine tool industry standard, so customers can rest assured for its excellent reliability while enjoying its high accuracy. It is mainly used for friction stir welding of large-format two-dimensional sealing structures such as new energy battery pack shells and large water-cooled plates.

In addition, for large-thickness and large-format special friction stir welding of aluminum alloy, it supports automatic welding of large-format 3D welds with a thickness of 40 mm on one side, a maximum length of 20 m and a maximum width of 16 m. The equipment is provided with the configurable double-beam gantry, double differential spindles, heavy-duty A/C swing head, drawback friction stir welding spindle, high-precision large-torque turntable, and constant pressure control. It integrates the tooling for milling and welding, and offers such functions as adaptive locating and clamping. For the special friction stir welding of large aluminum alloy storage tanks, the equipment supports φ800 mm-φ5,000 mm horizontal circumferential welds and φ800 mm-φ5,000 mm vertical longitudinal welds. It has the functions of multi-axis drive, drawback spindle, inner lining drive, outer ring digital pressing, etc.